Harvesting is a time-critical and important task. Belts are a vital part of your machine’s performance. Lost time from breakdowns or inefficient power transfer is not only frustrating but can result in lost revenue.

At RDO Equipment, we believe every drive belt produced for a John Deere Combine Harvester should be precisely developed with defined dimensions. Genuine John Deere belts feature a distinct rubber mix and Aramid cords that have been custom designed for heavy duty loads experienced while harvesting.

The significance in selecting the right belt for the application cannot be overstated. It is essential to ensure optimised up-time and life from the belt and the systems components. If a belt is inferior, whilst the upfront costs may be less, if it doesn’t perform the same amount of hours is it really better value?

WHY IS GENUINE BETTER?

BETTER PERFORMANCE –

Unique design: Genuine belts feature a distinct rubber mix and Aramid cords, and are specifically designed for heavy duty loads.

Heavy duty: Genuine belts are extremely strong and allow maximum power transmission without stretching.

MORE UPTIME –

Fewer parts: John Deere Combine Harvesters feature a reduced number of greasing points and fewer belts and chains, which means less wear parts than competitive machines.

Durable parts: Strong components help reduce the risk of breakdown, which means more uptime.

LOWER COST OF OPERATION –

Longer service intervals: John Deere Combine Harvesters require fewer belts and chains, which means longer service intervals and cost savings when compared to competitive machines.

Affordable parts: Our prices cut your costs. Fewer parts are required to maintain your machine, and the parts you do need are competitively priced.

THE DIFFERENCES

The risk of a belt failure is most often caused by flaws not externally noticeable. By understanding the differences in the belts and how they are made, more appropriate decisions can be made.

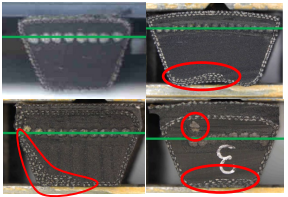

The four images below demonstrate the cross sections of combine belts from John Deere (top left) and three other competitors.

The John Deere belt demonstrates the precision and symmetry of the manufacturing process which cannot be seen in the other examples. The three competitor belts have informalities circled to highlight the difference in quality. It can be seen that the belts do not have consistent outer layers and the internal cords are smaller with less symmetry.

QUALITY COMPARISON

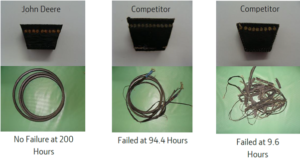

Furthermore, John Deere have carried out testing to confirm that the genuine belts are the best they can be, the three examples below are another representation of the significance in the belt quality regarding up-time. This test was performed under the same loads, speeds and conditions with the results shown below.

The competitors’ belts both failed during the 200-hour test.

Contact your local RDO team to find out more.

MyDealer:

MyDealer: